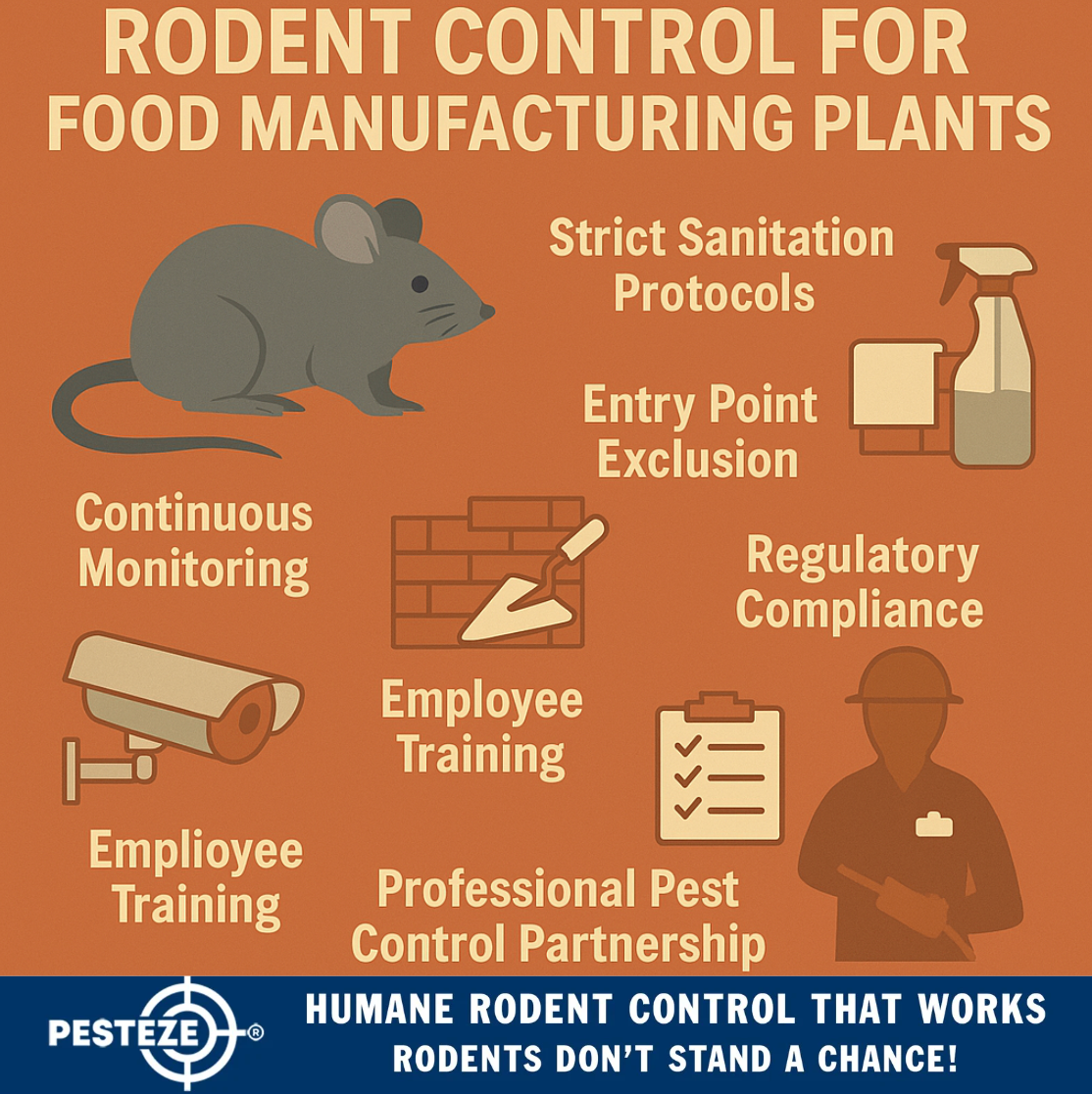

RODENT CONTROL FOR FOOD MANUFACTURING PLANTS

RODENT CONTROL FOR FOOD MANUFACTURING PLANTS

SUMMARY

Rodents pose serious risks in food manufacturing plants by contaminating ingredients, damaging equipment, and violating health regulations. Effective control measures are essential to protect product quality, maintain compliance, and ensure a safe production environment.

FEATURES

-

Strict Sanitation Protocols: Maintain spotless production and storage areas.

-

Entry Point Exclusion: Seal cracks, floor drains, and dock doors.

-

Continuous Monitoring: Use traps, cameras, and tracking systems.

-

Employee Training: Educate staff on identifying and reporting signs of infestation.

-

Regulatory Compliance: Follow FDA, USDA, and HACCP pest management standards.

-

Professional Pest Control Partnership: Schedule routine inspections and maintenance.

DESCRIPTION

In food manufacturing environments, rodent control is not optional—it’s a regulatory requirement and a cornerstone of operational safety. Rodents can contaminate products with droppings, urine, and fur, leading to costly recalls and reputational damage. To maintain compliance and protect food safety, manufacturers must implement an integrated, facility-wide rodent management plan.

Sanitation is the first line of defense. Every production and storage area should be cleaned regularly, with special attention given to spills, residue buildup, and hard-to-reach spaces under equipment or shelving. Waste bins must have tight-fitting lids and be emptied frequently to prevent attracting pests.

Exclusion is equally vital. Mice and rats can squeeze through tiny gaps in walls, loading docks, and ventilation systems. Seal cracks with durable materials such as metal mesh and concrete, and ensure doors and windows close tightly. Installing door sweeps and air curtains at loading areas helps block entry.

Monitoring systems provide early detection. Smart traps, cameras, and tracking stations placed along walls, near machinery, and in storage zones help detect rodent activity before it escalates.

Employee awareness strengthens overall prevention. Training workers to recognize droppings, chewed packaging, or nests encourages faster reporting and immediate corrective action. A proactive team can prevent infestations from spreading unnoticed.

Compliance is critical. Food facilities must meet pest control regulations set by agencies like the FDA, USDA, and HACCP. Documentation of regular inspections, pest activity logs, and control measures ensures audit readiness and public safety assurance.

Partnering with a certified pest control company specializing in food industry environments ensures that all preventive and corrective actions meet professional standards. They can customize treatment programs, provide reporting tools, and offer continual improvement recommendations.

By combining sanitation, exclusion, monitoring, and professional management, food manufacturing plants can maintain a safe, compliant, and rodent-free facility that protects both products and brand reputation.

- Saharsh Bansal

Comments 0